3D Modelling Proves Invaluable For Drilling Drains Project

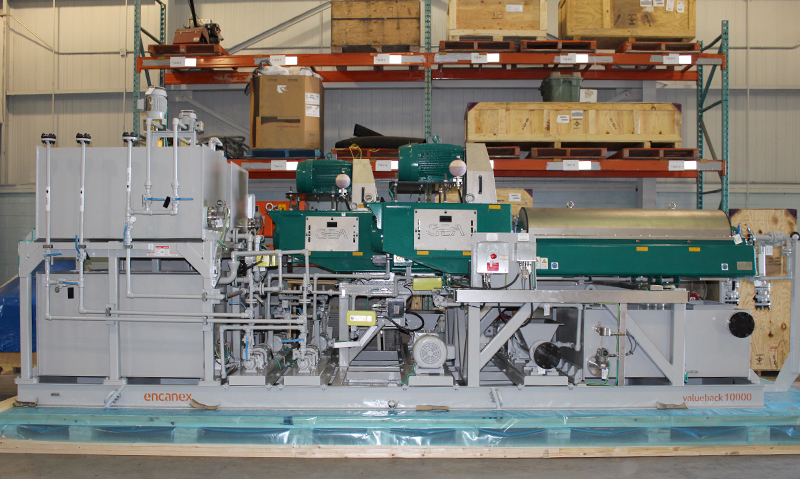

Encanex Environmental approached Allswater for a Drilling Drains Treatment Package for the offshore Hebron Project in Newfoundland and Labrador, Canada. Project scope included: engineering oversight and DNV approved structural, piping and mechanical design; integration of electrical and instrumentation design; and full-system integration. Working hand-in-hand with Encanex – already a repeat customer – every step of the way, we delivered an engineering package we’re proud of.

Challenge

Challenge

The Drilling Drains Treatment Package required four complex skid sets:

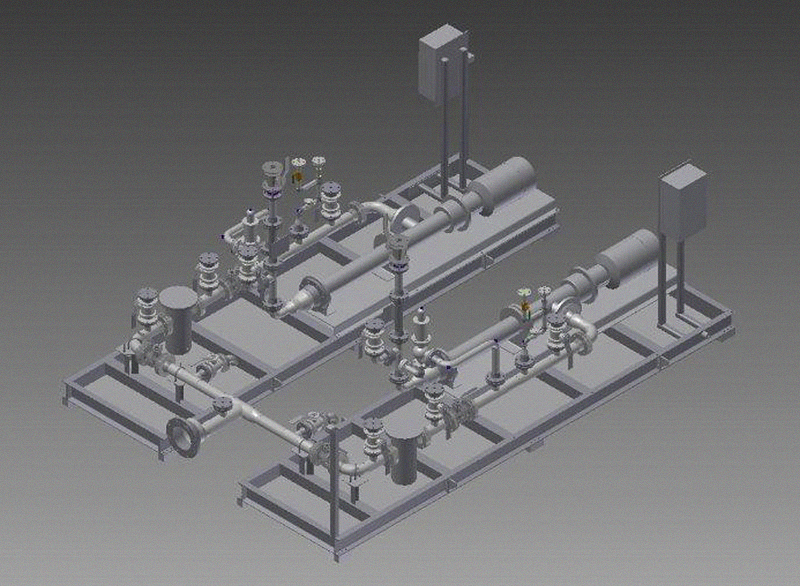

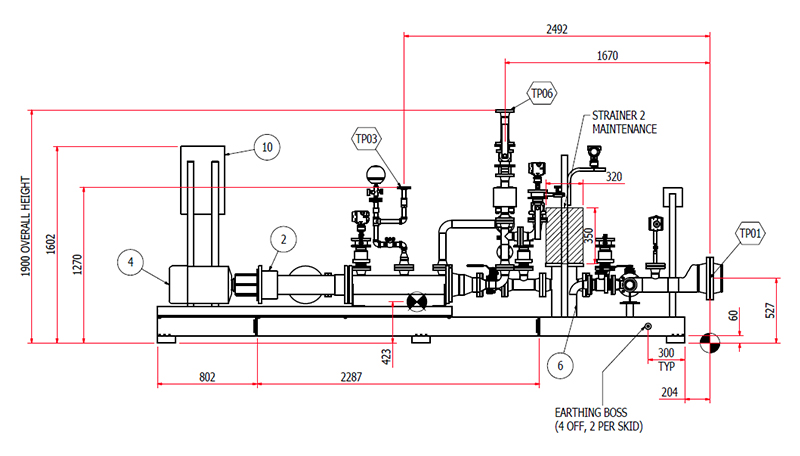

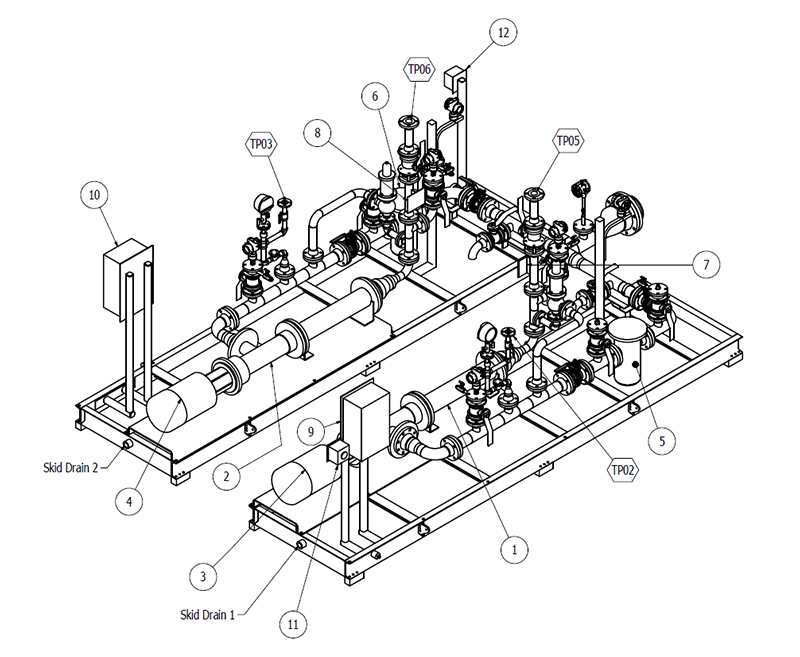

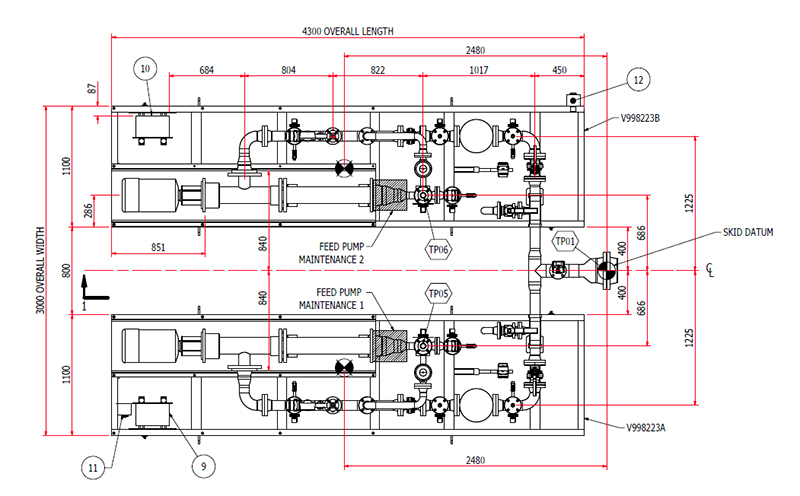

- Feed-Pump Skids: Two skids were needed to transfer hazardous drainage from a collection tank on the cellar deck.

- In-Line Skid Sets: Two additional skids were placed several decks above, where the separation processes occur, with treated water either discharging or diverting to a holding tank skid.

Encanex approached Allswater for this project due to our demonstrated expertise in the Oil and Gas sector, with a solid track record in NL, Nova Scotia (NS), and Alberta. Our Professional Engineers, licensed in the province of NL, provided essential engineering oversight and certification of design-critical documents.

Solution

Solution

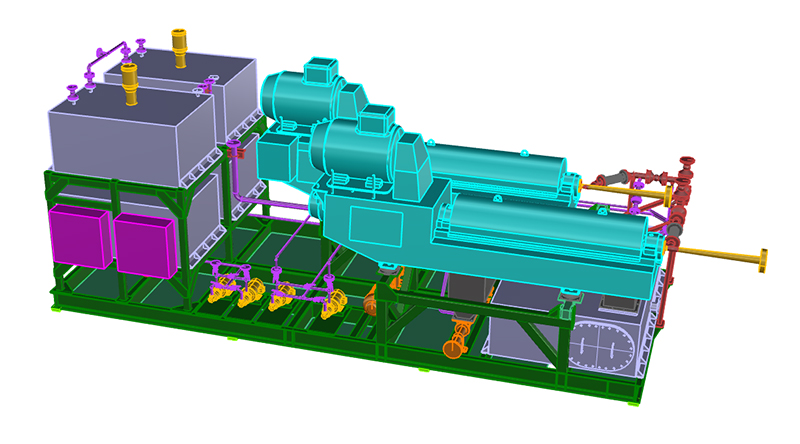

This project presented numerous engineering challenges, all of which were met by Allswater’s multi-disciplined team of project managers, engineers, and technologists:

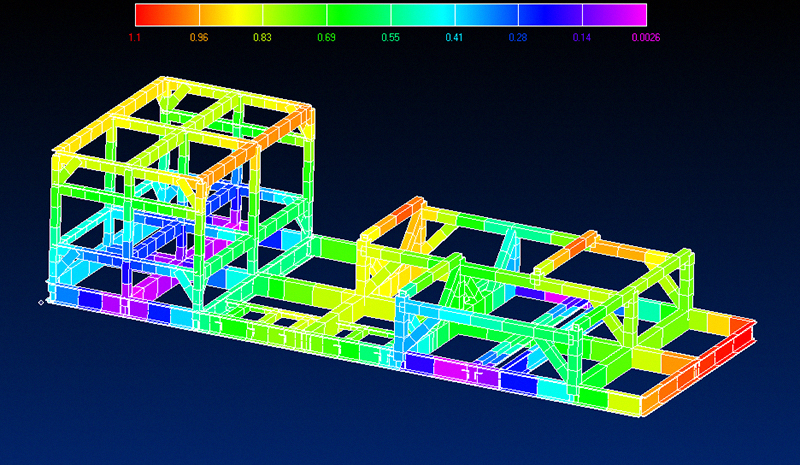

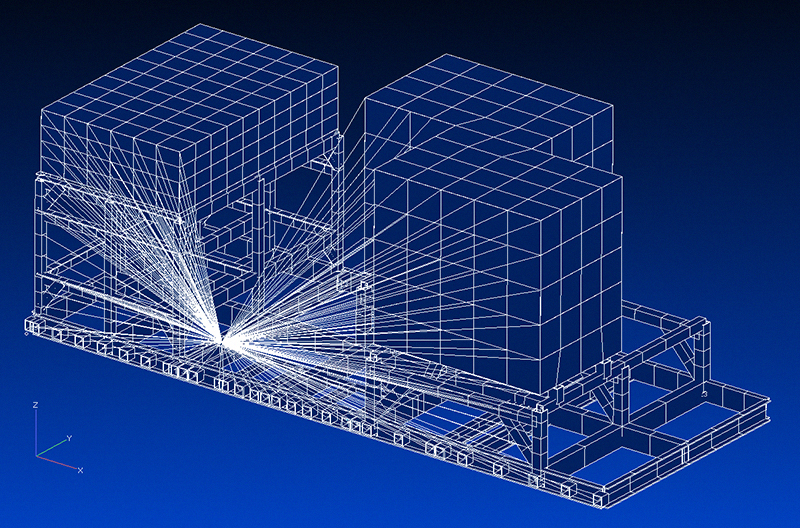

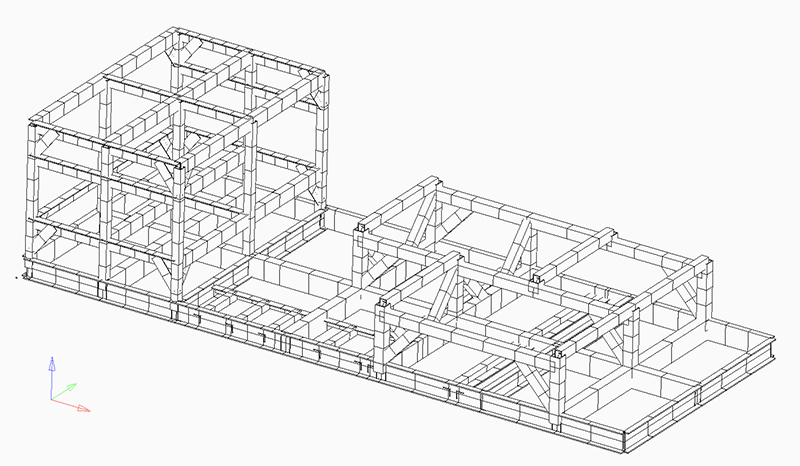

- Structural Design: The skids were designed to withstand significant shock and seismic loads, engaging our Finite Element Analysis experts to ensure resilience.

Complex Integration: The complexity of the package equipment, combined with the integration of piping, electrical, and instrumentation systems into the structural bases, made envisioning the final product challenging. Allswater’s team utilized the latest 3D modeling software to bring the skids to life, allowing for comprehensive reviews from the earliest design stages through to fabrication.

Results

3D Modeling Success: The use of 3D modeling software proved invaluable, identifying and correcting interferences early in the process, ensuring that purchased equipment and components fit perfectly prior to procurement. The 3D models provided a platform for all project team members, both technical and non-technical, to observe the models evolve from concept to final design.

Quality Feedback: Feedback from DNV on a structural report highlighted our commitment to quality. As Det Norske Veritas (U.S.A.) Inc. noted:

“The quality of structural steel calculations reports submitted were of the top quality. I was very impressed with the quality and type of responses we got for open comments.”

The quality of structural steel calculations reports submitted were of the top quality. I was very impressed with the quality and type of responses we got for open comments

<em>Det Norske</em><em>Veritas (U.S.A.)</em> <em>Inc</em>

Allswater was honored to contribute to this project located just off our shores, where the Drilling Drains Treatment Package will operate in one of the harshest marine environments for the next 30 years—a legacy estimated at 700 million barrels, and one we are thrilled to be part of.