Barge Project Completed With Minimal On-Site Welding

IndustryOffshore Oil & Gas

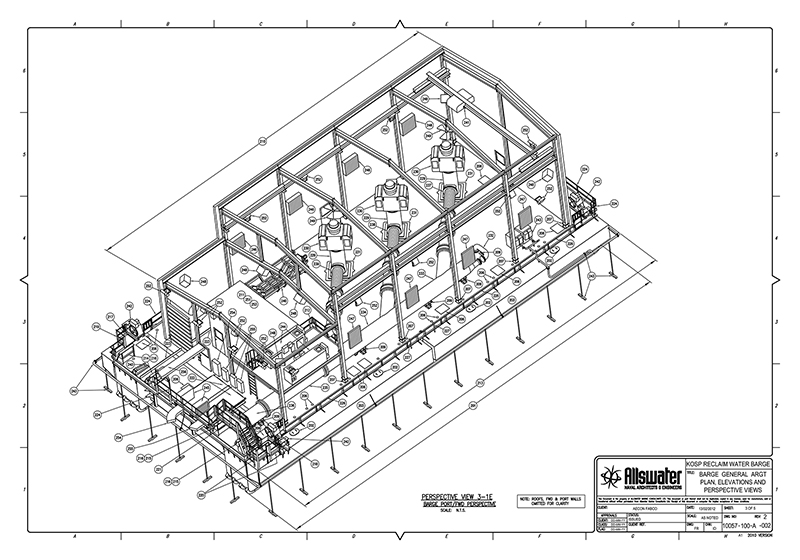

Allswater designed and integrated all systems for the Reclaim Water Pump Barge at Imperial Oil’s Kearl Oil Sands development. The barge is capable of processing between 4,000m3/hour and 13,500m3/hour of reclaim water from the tailings pond to the recycle water pond. The barge is capable of being floated to new locations over its 50-year service life.

Challenge

Northern Alberta is one of the most expensive construction locations on the planet. To deliver a cost-effective solution under these challenging conditions, it was essential to fabricate the barge’s main structures offsite, reducing on-site costs and complexities.

Solution

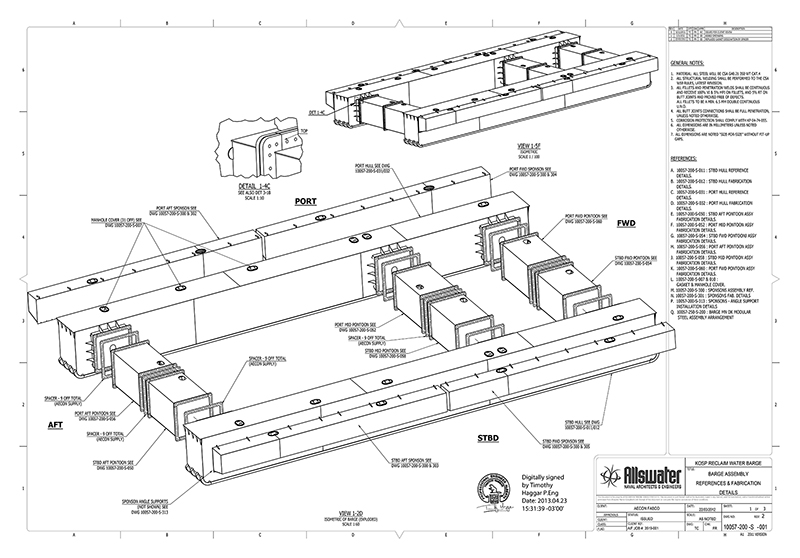

- Prototype Development: Created a modular barge system prototype that balanced key design considerations:

- Minimizing Buoyancy Volume and Steel Hull Weight: Ensuring the barge remained lightweight and efficient.

- Maximizing Module Sizes for Transportation: Facilitating easier transport across Canada.

- Optimized Build Strategy: Developed a strategy focused on:

- Bolted Assembly: Utilizing bolted connections for major hull components to streamline fabrication and assembly processes.

- Interdisciplinary Approach: Applied a highly inter-disciplinary methodology to navigate competing constraints and project requirements effectively.

- Technical Coordination: Led the technical interfacing among various engineering disciplines, including:

- Naval architecture

- Civil engineering

- Structural engineering

- Process piping

- HVAC

- Electrical engineering

- Mechanical engineering

- Leadership in Technical Teams: Directed technical teams in developing and executing methods for:

- Fabrication

- Transportation

- Sub-assembly

- Final assembly processes

- Project Management Support: Acted as an extension of the prime contractor’s project management team by providing:

- Technical and commercial support throughout the entire project lifecycle

- Document Management: Delivered reliable document management services for all engineering deliverables, coordinating inputs from:

- Engineering firms

- Shop drawing offices

- Suppliers and sub-contractors

Results

- Successful Installation: The barge was installed within the project’s transportation constraints with minimal on-site welding.

- Early Commissioning: Commissioned well in advance of the client’s “first oil” date, demonstrating efficiency and proactive project management.

- High Equipment Availability: Currently operating at high levels of equipment availability, ensuring reliable performance.

- Market Expansion: The project solidified Allswater’s presence in the natural resources pump barge market segment. This success is evidenced by:

- Second Order from Imperial Oil: Imperial Oil ordered a second sister-ship based on Allswater’s design to double the capacity of Kearl’s in-process water reclamation.

- Ongoing Support: Allswater continues to support numerous pump barge projects in Alberta, providing expertise in:

- Barge launches

- Hull designs

- Mooring analyses

- Lifting and relocation engineering plans and studies