Ro-Ro Ferry Emergency Bow Door Repair

When structural issues were identified in the steel framework supporting the bow door mechanism on a Ro-Ro passenger ferry, the operator turned to Allswater for urgent assistance. Our team promptly mobilized, conducting a thorough investigation, delivering targeted solutions, and providing detailed plans to facilitate a swift and effective repair.

Challenge

- Urgency: The vessel needed to return quickly to service to minimize disruption to the passenger service.

- Coordination: Managing the engineered solution and planning among the crew, operator, the Classification Society, and the repair contractor.

- Root Cause Analysis: Determining the cause of the steel deformation to prevent future issues.

Solution

Survey Work

Allswater swiftly conducted an extensive survey of the vessel, meticulously documenting the damage and taking detailed measurements. Consultations with the crew and operator provided critical insights into the damage timeline and operational factors that may have contributed. The investigation revealed that improper load distribution had caused structural stress, leading to deformation at a key frame.

Analysis

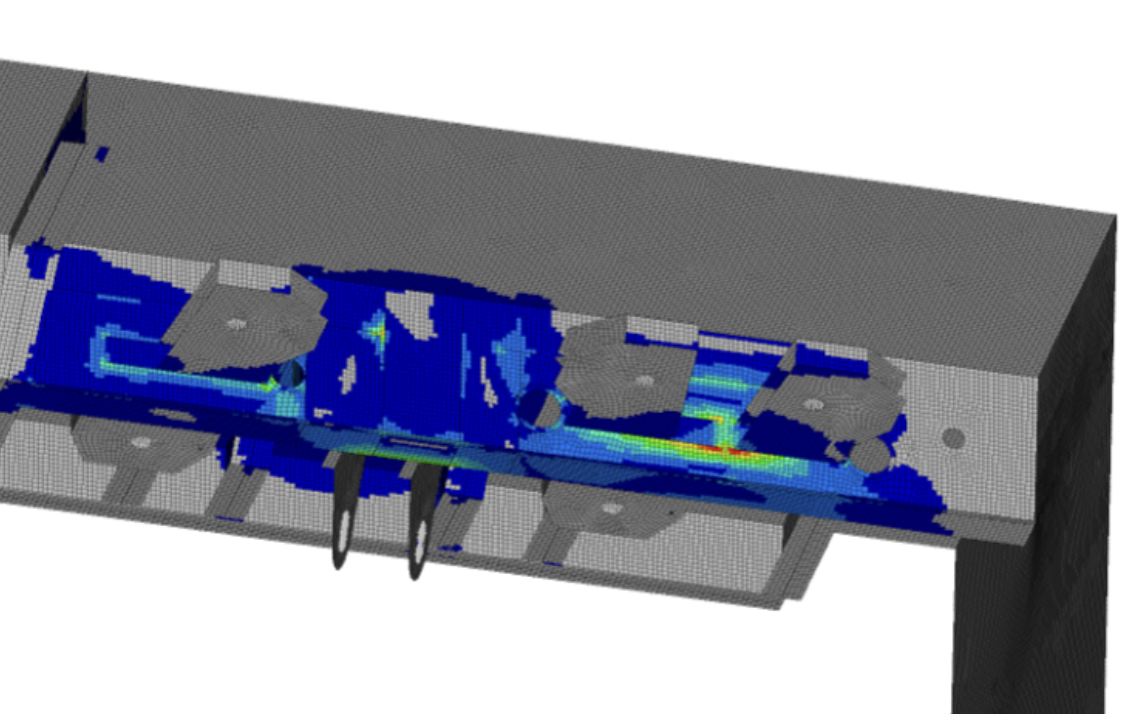

Using data from the survey, Allswater developed a Finite Element Analysis (FEA) model to pinpoint high-stress areas within the structure. This analysis guided the design of a comprehensive repair plan, ensuring the most critical areas were reinforced effectively.

Results

Allswater delivered a complete repair package, including:

- Detailed Drawings: Strip-out and installation instructions for the replacement of damaged components.

- Operational Recommendations: Procedures to prevent recurrence of structural stress.

- Regulatory Compliance: Ensuring all plans met Classification Society standards.

With Allswater’s rapid response and expertise, the bow door was quickly restored to full functionality, allowing the ferry to resume safe and reliable operations with minimal downtime.