Fast Track Helideck Installation

FULL DESCRIPTION

With four months of work already underway and a tight deadline looming, our client needed serious help completing their helideck installation project. Given Allswater’s experience with helideck design and installation, we were first on their call list and eager to assist ¬– with an efficient solution that kept the project on schedule and on budget.

CHALLENGES

- To meet the project’s deadline and specifications, Allswater had to reengineer the helideck, reduce its weight and obtain approvals while under an extremely tight timeline.

- All work had to be planned and scheduled in a way that reduced our client’s on-hire time and maintained the project budget.

- The project had to meet the requirements of DNVGL and CAP 437 (Standards for Offshore Helicopter Landing Areas).

SOLUTION/APPROACH

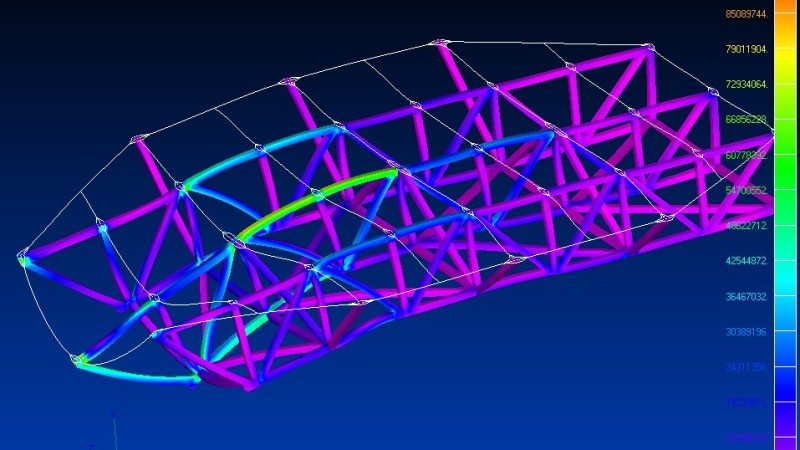

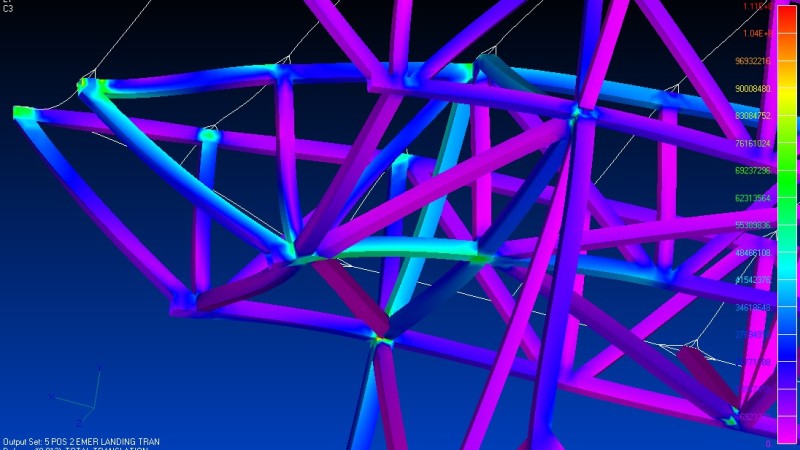

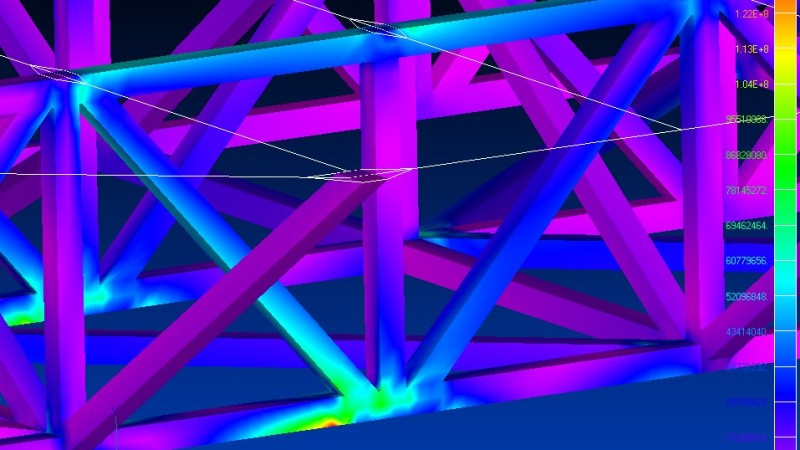

Using a nimble and efficient approach, Allswater relied on our vast helideck design experience to quickly provide a new solution. The new and improved design included structural, piping and mechanical design and engineering. Finite element analysis was used extensively to realize the required weight reductions and expedite the approval process.

RESULTS

Allswater turned the project around in just six weeks, producing a comprehensive new design that was one half the weight of the original, quickly approved, and immediately ready for fabrication. This All In approach resulted in Allswater being retained to help with a second helideck installation project for a very satisfied client.